New post-harvest technology developed for fresh blueberries

Quimas, the Chilean company that developed SmartPac some years ago, have now launched a new device that combines an Modified Atmosphere bag (MAP) with they proprietary SO2 releasing film in one device.

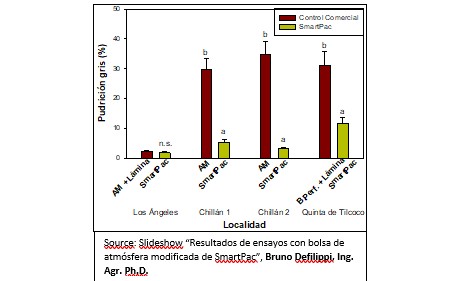

In a launch workshop done on September 5th in Santiago, Joseph Smilanick, plant pathologist and Ph.D. from UC Riverside and Bruno Defilippi, Agronomist and Ph.D. from UC Davis were present showing the studies done both in Chile at INIA La Platina and in USA, at the USDA ARS Laboratory. Both sources of data helped to fine-tune the device to reduce two of the most important post-harvest problems that blueberries have: Decay and softness.

Softness is highly related to water loss during post-harvest, so a MA bag helps reducing this problem by increasing the relative humidity inside the packaging. Conventional MA bags are not effective at controlling decay in blueberries, so here is where SmartPac’s technology comes in.

The characteristics of the SmartPac film matches very well with this challenge, as it can emit low and steady concentrations of SO2, an active ingredient known to be highly effective controlling mold development. SmartPac can emit for extended periods, and through all the surfaces of the bag, so the concentration is very homogeneous, avoiding any color or taste problem related to high SO2 concentration.

Final laboratory tests and semi-commercial trials have shown that SmartPac AM works as good as currently available MAP bag in terms of high humidity and softness reduction. Where the bag shines is in the mold control, consistently reducing the development of mold or Decay by 76% compared with a standard MA bag, as can be seen in the graph below. The slideshows shown during the workshop, and other technical info about SmartPac can be found in www.quimas.cl.

27/09/2018